I-BKM Series Of 2 Stages High Efficiency High Hypoid Geared Motor

Imininingwane Yomkhiqizo

Isici esikhulu sochungechunge lwe-BKM ukusebenza kahle kwayo kokudlulisela phambili, kufinyelela ngaphezu kwama-92%. Lokhu kuqinisekisa ukuthi amandla alethwa kahle emshinini wakho, okwandisa ukusebenza kwawo konke. Ngaphezu kwalokho, amagiya enziwe ngezinto ezisezingeni eliphezulu ze-alloy, aqiniswa phezulu, futhi asetshenzwa ngemishini yokugaya igiya enembayo. Lokhu kwenza amagiya anobuso obuqinile aqine kakhulu futhi amelane nokugqokwa.

Uma kukhulunywa ngokuthembeka, uchungechunge lwe-BKM luyagqama. Amakhabethe amamodeli ayisisekelo 050-090 enziwe nge-aluminium alloy yekhwalithi ephezulu ukuze kuqinisekiswe ukuthi awanakho ukugqwala futhi aqinile. Kumamodeli ayisisekelo 110 no-130, ikhabhinethi yenziwe ngensimbi ekhonjiwe yamandla angenakuqhathaniswa nokuqina. Ngaphezu kwalokho, ukusetshenziswa kwezikhungo zemishini eziqondile phakathi nenqubo yokukhiqiza kuqinisekisa ukunemba okuphezulu nokubekezelelana kwejometri.

Esinye isici esiphawulekayo ukusetshenziswa kwe-hypoid gear transmission, enezinga elikhulu lokudlulisela namandla aphezulu. Lokhu kuvumela uchungechunge lwe-BKM ukuthi luphathe izinhlelo zokusebenza ezisindayo kalula. Ngaphezu kwalokho, ubukhulu bokufakwa kwalesi sinciphisi segiya sihambisana ngokugcwele ne-RV series worm gear reducer, siyenza ihlangane futhi ilungele izindawo ezincane.

Ukufingqa, uchungechunge lwe-BKM lwezinciphisi zegiya ze-hypoid ezisebenza kahle kakhulu ziyizixazululo ezinokwethenjelwa nezinamandla zezinhlelo zokusebenza ezihlukene zezimboni. Ngokusebenza kwaso okuvelele, ukwethembeka okuvelele nokuqina okungenakuqhathaniswa, lesi sinciphisi segiya siqinisekile ukuthi sizokhuphula umkhiqizo futhi senze ukusebenza kahle kunoma iyiphi indawo yezimboni. Khetha i-BKM Series futhi uzwe umehluko ekusebenzeni kahle nokuthembeka.

Isicelo

1. Amarobhothi ezimboni, i-Industrial Automation, imboni yokukhiqiza ithuluzi lomshini we-CNC.

2. Imboni yezokwelapha, imboni yezimoto, ukuphrinta, ezolimo, imboni yokudla, ubunjiniyela bokuvikelwa kwemvelo, imboni yokugcinwa kwempahla.

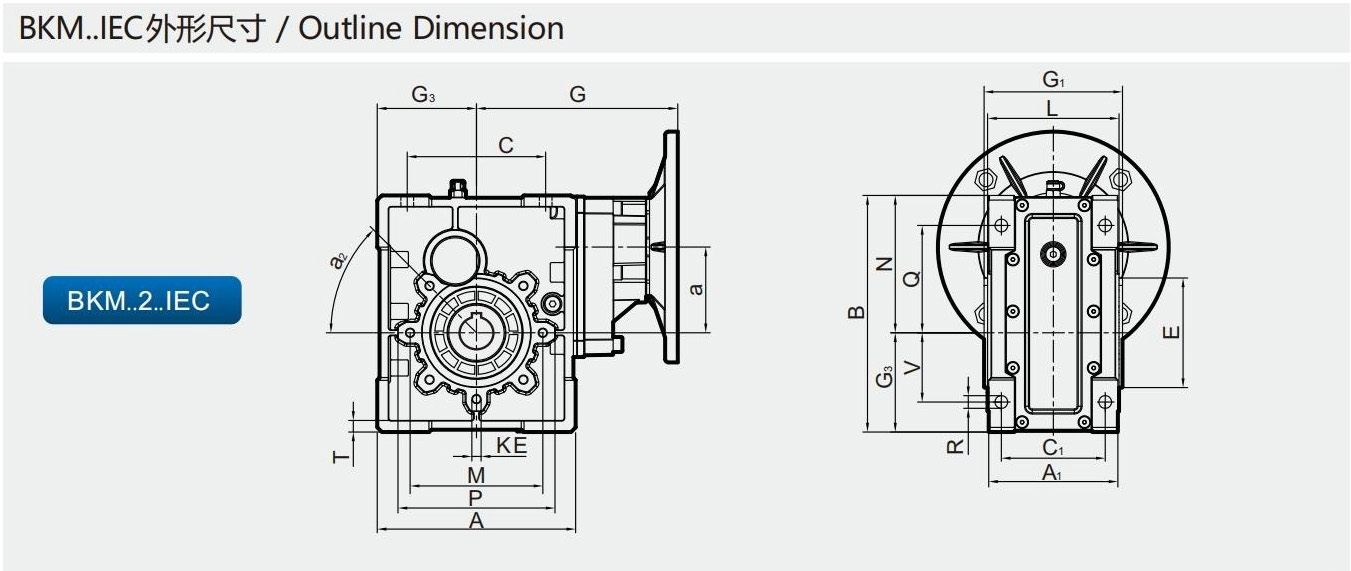

| I-BKM | C | A | B | G | G3 | a | C1 | KE | a2 | L | G1 | M | Eh8 | A1 | R | P | Q | N | T | V | kg |

| 0502 | 80 | 120 | 155 | 132.5 | 60 | 57 | 70 | 4-M8*12 | 45° | 87 | 92 | 85 | 70 | 85 | 8.5 | 100 | 75 | 95 | 8 | 40 | 4.1 |

| 0632 | 100 | 44 | 174 | 143.5 | 72 | 64.5 | 85 | 7-M8*14 | 45° | 106 | 112 | 95 | 80 | 103 | 8.5 | 110 | 80 | 102 | 9 | 50 | 6.3 |

| 0752 | 120 | 172 | 205 | 174 | 86 | 74.34 | 90 | 7-M8*16 | 45° | 114 | 120 | 115 | 95 | 112 | 11 | 140 | 93 | 119 | 10 | 60 | 10.3 |

| 0902 | 140 | 205 | 238 | 192 | 103 | 88 | 100 | 7-M10*22 | 45° | 134 | 140 | 130 | 110 | 130 | 13 | 160 | 102 | 135 | 11 | 70 | 13.5 |

| 1102 | 170 | 255 | 295 | 178.5 | 127.5 | 107 | 115 | 7-M10*25 | 45° | 148 | 155 | 165 | 130 | 144 | 14 | 185 | 125 | 167.5 | 14 | 85 | 41.5 |

| 1302 | 200 | 293 | 335 | 184.4 | 146.5 | 123 | 120 | 7-M12*25 | 45° | 162 | 170 | 215 | 180 | 155 | 16 | 250 | 140 | 188.5 | 15 | 100 | 55 |

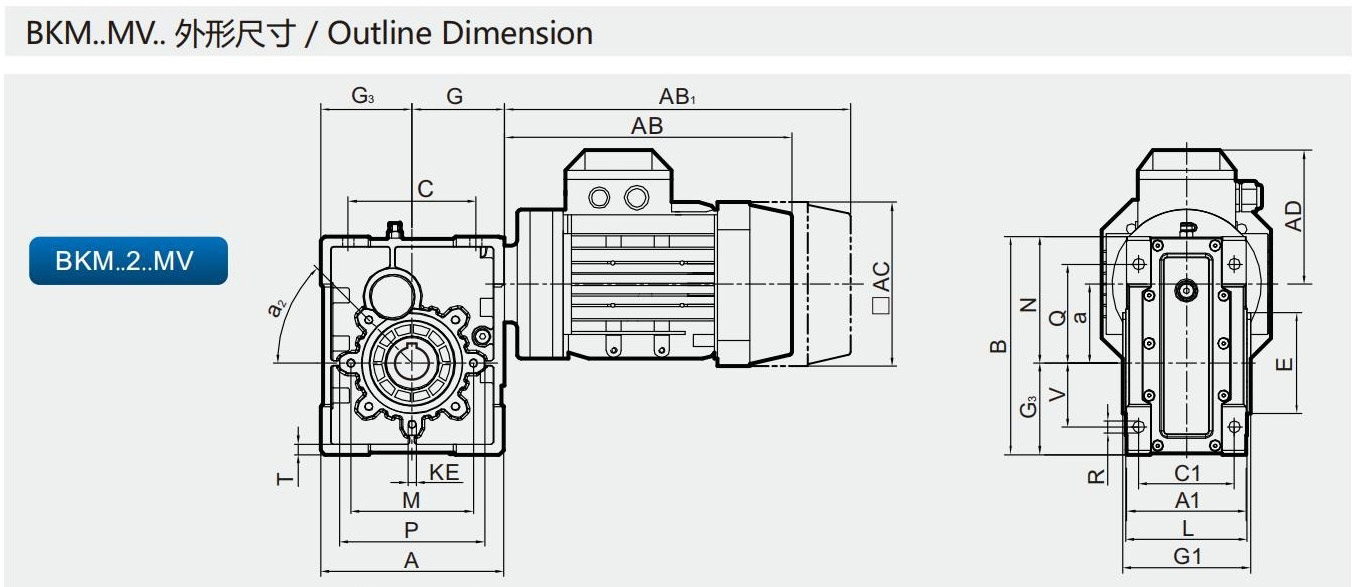

| I-BKM | C | A | B | G | G₃ | a | C | KE | a2 | L | G | M | Eh8 | A1 | R | P | Q | N | T | V |

| 0502 | 80 | 120 | 155 | 61 | 60 | 57 | 70 | 4-M8*12 | 45° | 87 | 92 | 85 | 70 | 85 | 8.5 | 100 | 75 | 95 | 8 | 40 |

| 0632 | 100 | 144 | 174 | 72 | 72 | 64.5 | 85 | 7-M8*14 | 45° | 106 | 112 | 95 | 80 | 103 | 8.5 | 110 | 80 | 102 | 9 | 50 |

| 0752 | 120 | 172 | 205 | 87 | 86 | 74.34 | 90 | 7-M8*16 | 45° | 114 | 120 | 115 | 95 | 112 | 11 | 140 | 93 | 119 | 10 | 60 |

| 0902 | 140 | 205 | 238 | 104 | 103 | 88 | 100 | 7-M10*22 | 45° | 134 | 140 | 130 | 110 | 130 | 13 | 160 | 102 | 135 | 11 | 70 |

| MV.. | 63 | 71 | 80 | 90S | 90L | 100 | 112 | 132 |

| AB | 207 | 235 | 250 | 286 | 296 | 320 | 360 | 410 |

| AB1 | 267 | 305 | 320 | 370 | 370 | 400 | 440 | 507 |

| AC | 120 | 130 | 145 | 160 | 160 | 185 | 200 | 245 |

| AD | 104 | 107 | 115 | 122 | 122 | 137 | 155 | 180 |