BKM..HS Series Of Shaft Input High Efficiency High Helical Hypoid Gearbox

Imininingwane Yomkhiqizo

Ukuthembeka kubalulekile kunoma iyiphi isethi yegiya, futhi amasethi egiya le-BKM hypoid aklanyelwe ukuhlinzeka ngokusebenza okuhle kakhulu esikhathini eside. Izindlu zakhiwe nge-alloy ye-die-cast aluminium, eyaziwa ngamandla ayo nokuqina. Lokhu kwakhiwa okumazombezombe kuqinisekisa ukuthi iyunithi yegiya ingakwazi ukumelana nezimo zokusebenza ezinzima futhi inikeze isevisi ehlala isikhathi eside.

Ngaphezu kokucaciswa kwezobuchwepheshe, ama-gearbox e-BKM hypoid aklanywe kucatshangwa ngokufaneleka komsebenzisi. Iqinisekisa ukufakwa kalula, ukugcinwa nokusebenza, okuvumela amakhasimende ukuthi onge isikhathi nezinsiza. Kungakhathaliseki ukuthi ungunjiniyela, uchwepheshe noma u-opharetha, ukusebenzisa lawa mayunithi egiya ngeke kube yinto ekhathazayo.

Sekukonke, iyunithi yegiya ye-BKM hypoid iyisixazululo esiguquguqukayo, esisebenza kahle kakhulu futhi esithembekile sezinhlelo zokusebenza ezihlukahlukene zokudlulisa amandla. Atholakala ngosayizi abayisisekelo abayisithupha, enamandla okusebenza angu-0.12-7.5kW, itorque engu-1500Nm kanye nebanga lika-7.5-300 lika-gearbox, lawa magiya aletha ukusebenza kahle nokusebenza kahle. Ngokwakhiwa kwawo okuqinile kanye nomklamo osebenziseka kalula, amayunithi egiya e-BKM hypoid ayinketho yokuqala ezimbonini ezifuna izixazululo zokudlulisa amandla ezisezingeni eliphezulu.

Isicelo

1. Amarobhothi ezimboni, i-Industrial Automation, imboni yokukhiqiza ithuluzi lomshini we-CNC.

2. Imboni yezokwelapha, imboni yezimoto, ukuphrinta, ezolimo, imboni yokudla, ubunjiniyela bokuvikelwa kwemvelo, imboni yokugcinwa kwempahla.

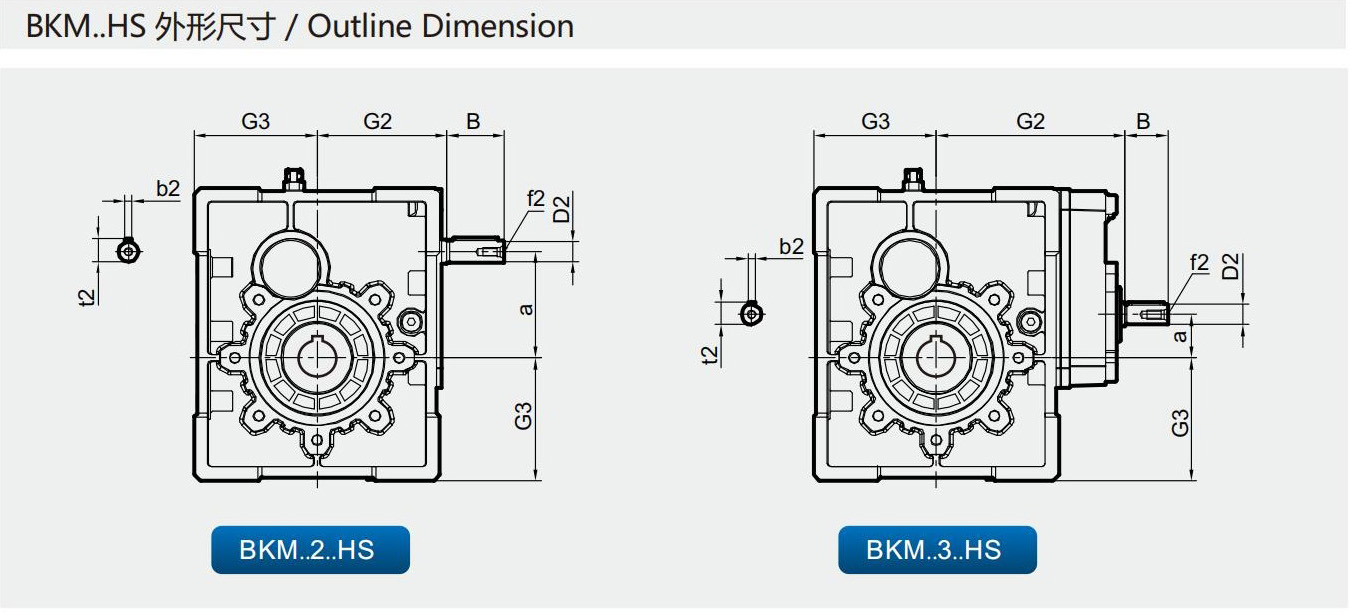

| I-BKM | B | D2j6 | G₂ | G₃ | a | b₂ | t₂ | f₂ |

| 0502 | 23 | 11 | 65 | 60 | 57 | 4 | 12.5 | - |

| 0503 | 23 | 11 | 100 | 60 | 21.5 | 4 | 12.5 | - |

| 0632 | 30 | 14 | 76 | 72 | 64.5 | 5 | 16 | M6 |

| 0633 | 23 | 11 | 111 | 72 | 29 | 4 | 12.5 | - |

| 0752 | 40 | 16 | 91 | 86 | 74.34 | 5 | 18 | M6 |

| 0753 | 30 | 14 | 132 | 86 | 30.34 | 5 | 16 | M6 |

| 0902 | 40 | 19 | 107 | 103 | 88 | 6 | 21.5 | M6 |

| 0903 | 30 | 14 | 146 | 103 | 44 | 5 | 16 | M6 |

| 1102 | 50 | 24 | 165 | 127.5 | 107 | 8 | 27 | M8 |

| 1103 | 40 | 19 | 256 | 127.5 | 51 | 6 | 21.5 | M6 |

| 1302 | 60 | 28 | 171.5 | 146.5 | 123 | 8 | 31 | M10 |

| 1303 | 40 | 19 | 262 | 146.5 | 67 | 6 | 21.5 | M6 |