I-BABR Precision Planetary Gear Units

Ukwethembeka

● Ukulungiswa kwamagiya okuvunguza okutholwe ngesilinganiso sokuzibandakanya ngokuphindwe kabili kunamagiya avamile we-spur, kufaka phakathi isimo sokusebenza okushelelayo nomsindo ophansi, i-torque ephezulu ekhiphayo kanye ne-low back clearance.

● Amagiya enziwe ngensimbi eyingxubevange enekhwalithi ephezulu, esetshenziswa ngokwelashwa kokuqina kwendawo, agaywe ngegrinder enembayo ephezulu, enikeza isici esihle esingagugi kanye nokumelana nomthelela.

| Inombolo yemodeli | Isiteji | Isilinganiso | I-BABR042 | I-BABR060 | BABR090 | I-BABR115 | I-BABR142 | I-BABR180 | I-BABR220 | ||||||

| (I-Mominal Output Torque Tzn) | Nm | 1 | 3 | 9 | 36 | 90 | 195 | 342 | 588 | 1,140 | |||||

| 4 | 12 | 48 | 120 | 260 | 520 | 1,040 | 1,680 | ||||||||

| 5 | 15 | 60 | 260 | 325 | 650 | 1.200 | 2,000 | ||||||||

| 6 | 18 | 55 | 325 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 7 | 19 | 50 | 310 | 300 | 550 | 1,100 | 1,800 | ||||||||

| 8 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 10 | 14 | 60 | 150 | 325 | 90 | 1.200 | 2,000 | ||||||||

| 14 | - | 42 | 140 | 300 | 50 | 1,100 | 1,800 | ||||||||

| 20 | - | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 2 | 15 | 14 | - | - | - | - | - | - | |||||||

| 20 | 14 | - | - | - | - | - | - | ||||||||

| 25 | 15 | 60 | 150 | 325 | 650 | 1,200 | 2,000 | ||||||||

| 30 | 20 | 55 | 150 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 35 | 19 | 50 | 140 | 300 | 550 | 1.100 | 1,800 | ||||||||

| 40 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 50 | 14 | 60 | 100 | 230 | 650 | 1,200 | 2,000 | ||||||||

| 60 | 20 | 55 | 150 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 70 | 19 | 50 | 140 | 300 | 550 | 1.100 | 1,800 | ||||||||

| 80 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 100 | 14 | 40 | 150 | 325 | 650 | 1,200 | 2,000 | ||||||||

| 120 | - | - | 150 | 325 | 650 | 1,100 | 1,900 | ||||||||

| 140 | - | - | 140 | 300 | 550 | 1,100 | 1,800 | ||||||||

| 160 | - | - | 120 | 260 | 550 | 1,000 | 1,600 | ||||||||

| 180 | - | - | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 200 | - | - | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| (I-Emergency Stop Torque Tznor) | Nm | 1,2 | 3-200 | (Izikhathi ezi-3 ze-Mominal Output Torque) | |||||||||||

| (Isivinini Sokufaka Esivamile N1N) | rpm | 1,2 | 3-200 | 5,000 | 5,000 | 4, 000 | 4, 000 | 3, 000 | 3, 000 | 2, 000 | |||||

| (Isivinini Sokufaka Esivamile N1B) | rpm | 1,2 | 3-200 | 10,000 | 10,000 | 8, 000 | 8, 000 | 6, 000 | 6, 000 | 4, 000 | |||||

| (I-Micro Backiash PO) | arcmin | 1 | 3~20 | - | - | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |||||

| 2 | 12-200 | - | - | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |||||||

| (I-backlash P1 encishisiwe) | arcmin | 1 | 3~20 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |||||

| 2 | 2 ~ 200 | ≤7 | <7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | |||||||

| (Standard Backlash P2) | arcmin | 1 | U | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | |||||

| 2 | 2 ~ 200 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | |||||||

| Ukuqina kwe-torsion | Nm/arcnmin | 1,2 | 3~20 | 3 | 7 | 14 | 25 | 50 | 145 | 225 | |||||

| (Isikhathi sokugoba esiphezulu M2kB) | Nm | 1,2 | 3-200 | 780 | 1,530 | 3, 250 | 6, 700 | 9, 400 | 14, 500 | 50, 000 | |||||

| (I-radial force evumelekile F2aB) | N | 1,2 | 3-200 | 390 | 765 | 1, 625 | 3, 350 | 4, 700 | 7, 250 | 25, 000 | |||||

| (Impilo yesevisi) | hr | 1,2 | 3-200 | 20.000 | |||||||||||

| (Ukusebenza kahle) | % | 1 | 3~20 | ≤95% | |||||||||||

| 2 | 12-200 | ≤92% | |||||||||||||

| (Isisindo) | kg | 1 | 3~20 | 0.9 | 2.1 | 6.4 | 13 | 24.5 | 51 | 83 | |||||

| 2 | 2 ~ 200 | 1.2 | 1.5 | 7.8 | 14.2 | 27.5 | 54 | 95 | |||||||

| (ITemp Operating) | ℃ | 1,2 | 3-200 | 0°C+90°℃ | |||||||||||

| (Ukuthambisa) | 1,2 | 3-200 | Amafutha okugcoba okwenziwa | ||||||||||||

| (Iziqu zokuvikela i-Gearbox) | 1,2 | 3-200 | |P65 | ||||||||||||

| (Indawo Yokukhuphuka) | 1,2 | 3-200 | Zonke izikhombisi-ndlela | ||||||||||||

| Umsindo(n1=3000 rpmi=10, Awukho umthwalo) | I-dB(A) | 1,2 | 3-200 | ≤61 | ≤63 | ≤65 | ≤68 | ≤70 | ≤72 | ≤74 | |||||

Imininingwane Yomkhiqizo

PINSethula umkhiqizo wethu omusha, uchungechunge lokunciphisa. Ububanzi butholakala ngezinhlobonhlobo zokucaciswa, okuvumela amakhasimende ukuthi akhethe umkhiqizo ohambisana nezidingo zawo. Uchungechunge lwe-reducers luhlanganisa ukucaciswa okungu-7: 042, 060, 090, 115, 142, 180 kanye no-220, okuhlinzeka ngezinketho zezinhlelo zokusebenza ezihlukahlukene.

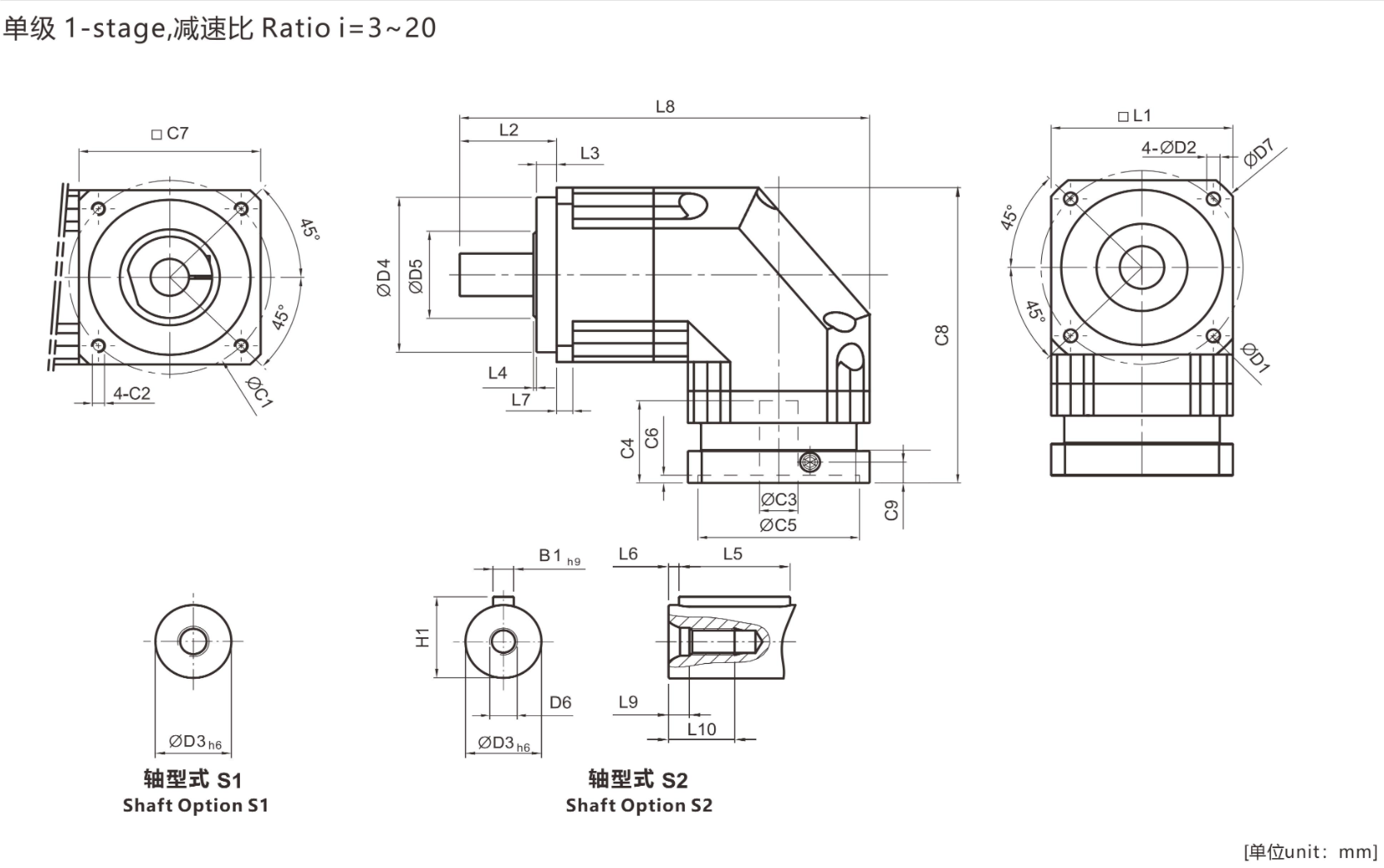

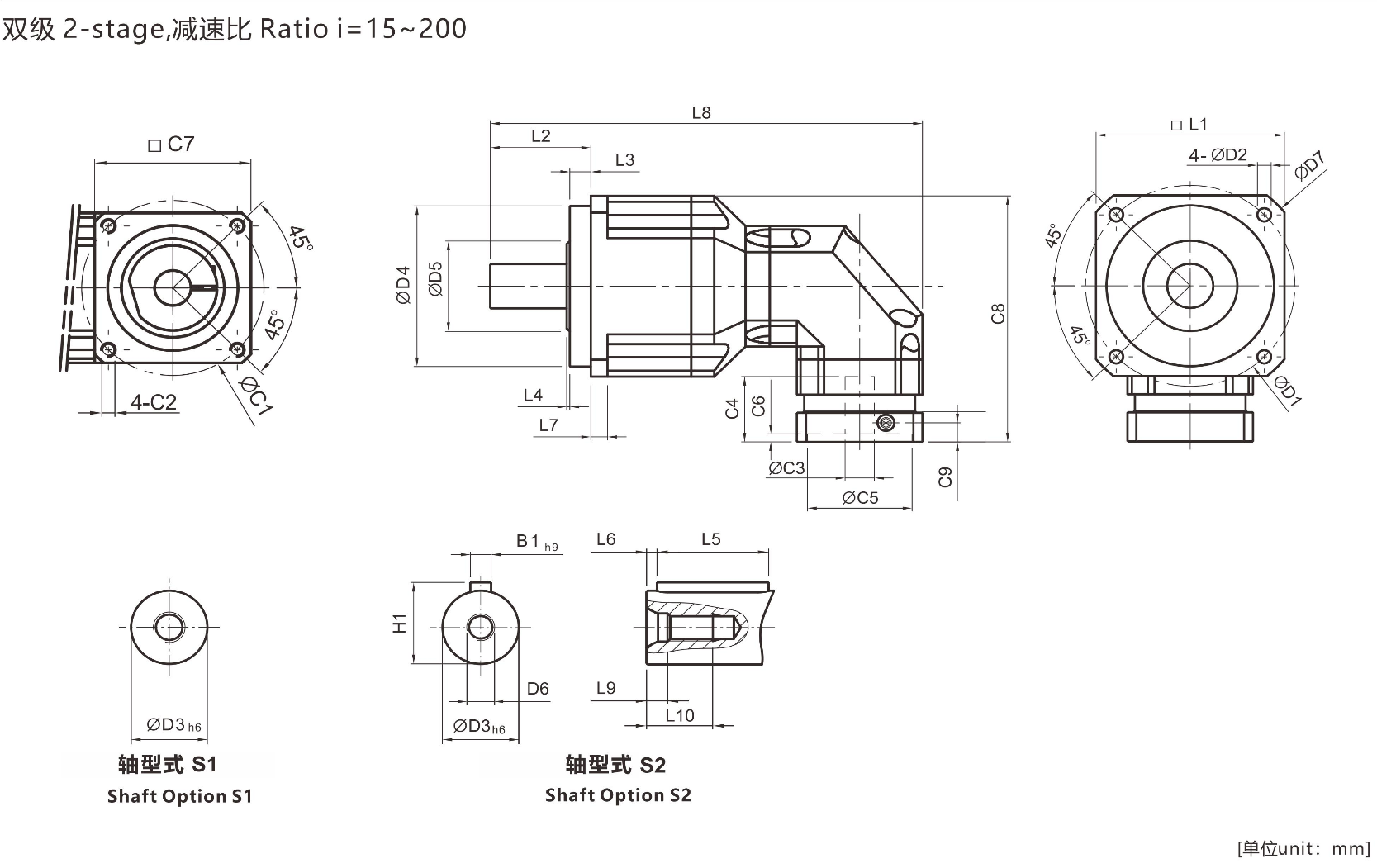

Uchungechunge lwethu lokunciphisa lune-torque elinganiselwe ephezulu kakhulu engu-2000Nm futhi lunikeza ukusebenza okuhle kakhulu. Ibanga lesilinganiso sokunciphisa isigaba esisodwa lisuka ku-3 ukuya ku-20, liqinisekisa ukulawula okunembayo nokusebenza kahle. Ukuze uthole ukuguquguquka okukhulu, siphinde sinikeze izigaba ezimbili ezinezilinganiso zokunciphisa ukusuka ku-15 kuye ku-200.

Esinye sezici eziyinhloko zebanga lethu lokunciphisa ukuthembeka kwalo. Ukwamukela idizayini edidiyelwe yokusekelwa okukabili ukuze kuthuthukiswe ukuqina namandla etorque. I-engeli engu-90° yokuphumayo ivumela ukufakwa okuguquguqukayo ezindaweni eziqinile kuyilapho inikezela ngezinketho zokudlulisela ezihlukahlukene.

Ukuqina kubaluleke kakhulu kithi, yingakho amagiya ebangeni lethu lokunciphisa enziwe ngezinto ezisezingeni eliphezulu ze-alloy. Lawa magiya aqiniswa ikesi futhi enziwe ngomshini kusetshenziswa izigaya zegiya ezinemba kakhulu, awanika ukumelana nokugqokwa okuhle kakhulu, ukumelana nomthelela kanye nokuqina.

Kungakhathaliseki ukuthi udinga ukulawula okunembile, ukusebenza kahle noma ukusebenza okuthembekile, uhla lwethu lwabanciphisi lungahlangabezana nezidingo zakho. Thembela ubuchwepheshe bethu futhi ukhethe uhla lwethu lokunciphisa iphrojekthi yakho elandelayo. Izwa umehluko ekusebenzeni nasekuthembekeni okulethwa yimikhiqizo yethu.

Isicelo

1. Inkambu ye-Aerospace

2. Imboni yezokwelapha

3. Amarobhothi ezimboni, i-Industrial Automation, imboni yezimoto ye-CNC yokukhiqiza ithuluzi lomshini, ukuphrinta, ezolimo, imboni yokudla, ubunjiniyela bokuvikela indawo, imboni yezimpahla zokugcinwa kwempahla.

| Ubukhulu | I-BABR042 | I-BABR060 | BABR090 | I-BABR115 | I-BABR142 | I-BABR180 | I-BABR220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| d3 h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| d4 g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | I-M4x0.7P | M5x0.8P | M8x1.25P | M12x1.75P | I-M16x2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 63 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 111.5 | 145 | 203 | 259 | 333 | 394 | 484 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 |

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C2¹ | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C3¹G7 | ≤11/≤12 | ≤14/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 25 | 34 | 40 | 50 | 60 | 85 | 116 |

| C5¹G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C6¹ | 3.5 | 4 | 6 | 5 | 6 | 6 | 6 |

| C71 | 42 | 60 | 90 | 115 | 142 | 190 | 220 |

| C8¹ | 90.5 | 111.5 | 152.5 | 191.5 | 235.5 | 303.5 | 378.5 |

| C9¹ | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53 |

| B1 h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

| Ubukhulu | I-BABR042 | I-BABR060 | BABR090 | I-BABR115 | I-BABR142 | I-BABR180 | I-BABR220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | I-M4x0.7P | M5x0.8P | M8x1.25P | M12x1.75P | I-M16x2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 63 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 139 | 163.5 | 206.5 | 285 | 365 | 431 | 521 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 100 | 12.5 | 19 | 28 | 36 | 42 | 42 |

| C11 | 46 | 46 | 70 | 100 | 130 | 165 | 215 |

| C2¹ | M4x0.7Px10 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px28 | M12x1.75Px28 |

| C3¹G7 | ≤11/≤12 | ≤11/≤12 | ≤14/≤15.875/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 |

| C41 | 25 | 25 | 34 | 40 | 50 | 60 | 85 |

| C5¹G7 | 30 | 30 | 50 | 80 | 110 | 130 | 180 |

| C61 | 3.5 | 3.5 | 4 | 6 | 5 | 6 | 6 |

| C71 | 42 | 42 | 60 | 90 | 115 | 142 | 190 |

| C81 | 90.5 | 99.5 | 126.5 | 165 | 205 | 254.5 | 323.5 |

| C91 | 8.75 | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 |

| B1h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |